A spray gun is a tool that is commonly used in the manufacturing industry to apply liquid substances onto a surface. Spray guns are versatile tools used in various applications, including painting, coating, and spraying. They are commonly used in manufacturing for applications such as spraying resin and curing agents for glass-reinforced plastic (GRP) materials. In this article, we will explore the different components of a spray gun system and how they work together to create an efficient and effective system.

Romas Machine Technology is a manufacturer of vacuum thermoforming machines and Spray guns. Our spraying machine absorbs advanced experience from a global perspective and develops a new generation of spraying machines based on 18 years of accumulation. The utility model has the advantages of high productivity, low gas consumption and flexible startup and shutdown.

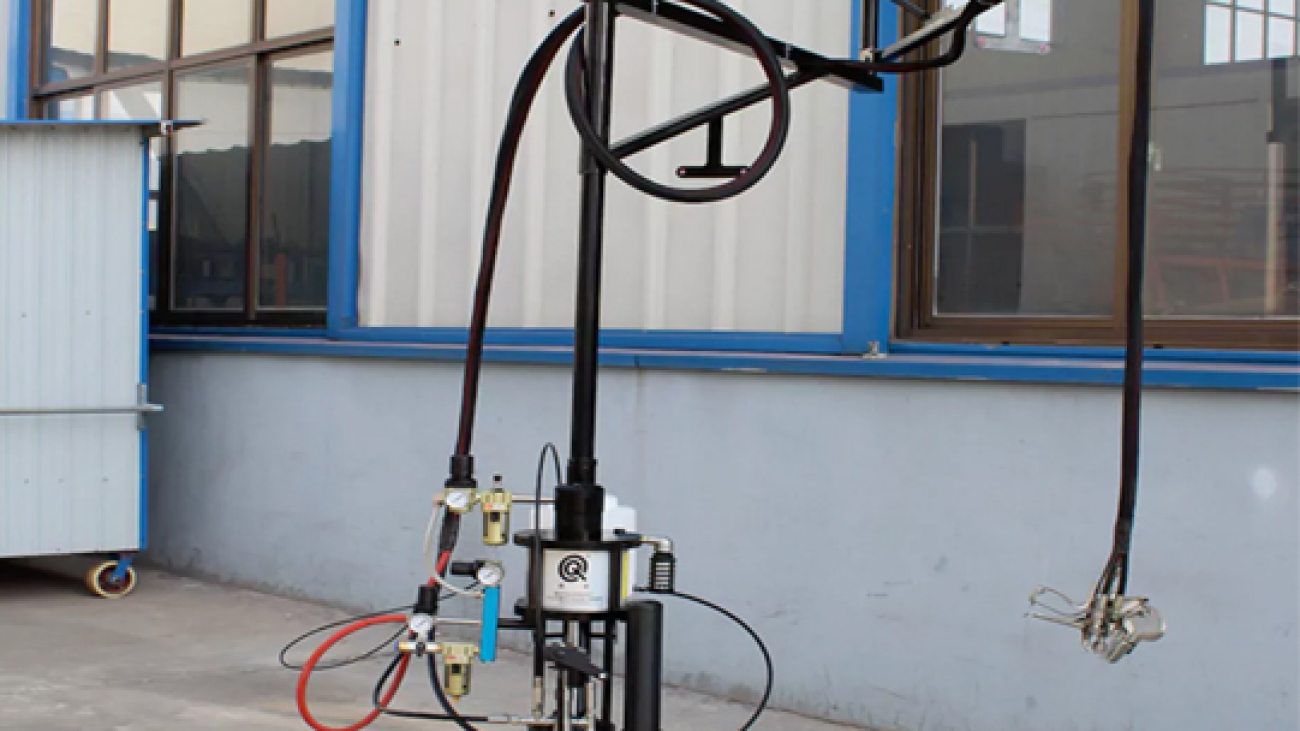

Our machines consist of a nozzle that is connected to a source of compressed air, which is used to atomize the liquid substance and spray it onto the surface.

Components of our Spray Guns

- Material Pump:

The material pump is an essential component of our spray gun system, as it is responsible for pumping the liquid substance from the storage tank to the spray gun itself. The CQP-15l / min is a type of material pump that is commonly used in spray gun systems.

This pump is designed to deliver a high flow rate of up to 15 litres per minute, which makes it ideal for use in high-volume applications. It is also highly efficient and reliable, which helps to ensure that the liquid substance is delivered to the spray gun in a consistent and uniform manner.

- Curing Agent Pump:

In addition to the material pump, our spray gun systems also include a curing agent pump. This pump is responsible for delivering the curing agent to the spray gun, where it can be mixed with the liquid substance and sprayed onto the surface.

The stainless steel servo pump is a popular choice for curing agent pumps, as it is highly durable and resistant to corrosion. It is also very precise, which helps to ensure that the correct amount of curing agent is delivered to the spray gun.

- Material Pipe:

The material pipe is the conduit through which the liquid substance is delivered from the storage tank to the spray gun. The length of the material pipe is an important consideration when designing a spray gun system, as it can impact the efficiency and effectiveness of the system.

A 15m material pipe is a common length of our spray gun systems, as it provides good balance between flexibility and efficiency. This length allows the spray gun operator to move around the work area without being restricted by the length of the pipe, while still delivering the liquid substance to the spray gun in a consistent and uniform manner.

- Curing Agent Pipe:

Like the material pipe, the curing agent pipe is also an important component of a spray gun system. It is responsible for delivering the curing agent from the storage tank to the spray gun, where it can be mixed with the liquid substance and sprayed onto the surface.

A 15m curing agent pipe is a common length of our spray gun systems, as it provides a good balance between flexibility and efficiency. This length allows the spray gun operator to move around the work area without being restricted by the length of the pipe, while still delivering the curing agent to the spray gun in a consistent and uniform manner.

- Lifting Pipe:

The lifting pipe is a component of our spray gun system that is used to raise and lower the spray gun itself. This is an important feature, as it allows the operator to adjust the height of the spray gun to ensure that the liquid substance is being applied to the surface at the correct distance and angle.

A 3m lifting pipe is a common length for our spray gun systems, as it provides a good range of motion without being too cumbersome or difficult to manoeuvre. This length allows the operator to adjust the height of the spray gun as needed, while still maintaining control over the system.

Our Advantages

Romas Machine Technology Co., Ltd. provides the greatest quality and versatility in screen printing machines. We focus on the market, the user, quality, development, and management while developing and managing our goods, which has helped us build a strong reputation with customers and offer competitive pricing.