Description

- Features of high-precision electric vertical screen printing machine

- The printing transmission is driven by a motor and a synchronous belt transmission, which has agile action, uniform speed, and adjustable speed. The lifting and lowering of the net frame is driven by a motor, frequency conversion speed regulation, and the whole machine runs smoothly.

- The squeegee and the ink-returning knife have air pressure adjustment devices, and the printing thickness and size can be adjusted.

- Pneumatic off-screen structure, which can be opened or closed according to printing needs, which is convenient and flexible.

- The screen arm can be adjusted left and right to facilitate the printing of different sizes of screens and products.

- Equipped with a safety device to make the grid stand at the upper position, with reliable safety.

- The left and right stroke is controlled by the proximity switch, which is easy to operate.

- The electronic control unit is centralized controlled by the microcomputer controller, the operation of the whole machine is simpler, more flexible and convenient for maintenance.

Technical parameters of high-precision electric vertical screen printing machine

Equipment lubrication part

Working environment

- The ambient light intensity shall not be greater than 3000Lx

- The temperature of the surrounding medium is not higher than -20

- The relative humidity of the air is not more than 85% (medium temperature is at 20℃)

- Places without conductive dust.

- An environment without explosion hazard.

- An environment free of gases and vapors that can corrode metals.

- Single-phase AC220V, 10KW power supply and 3-6kg/cm², 260L/min compressed air source supply place.

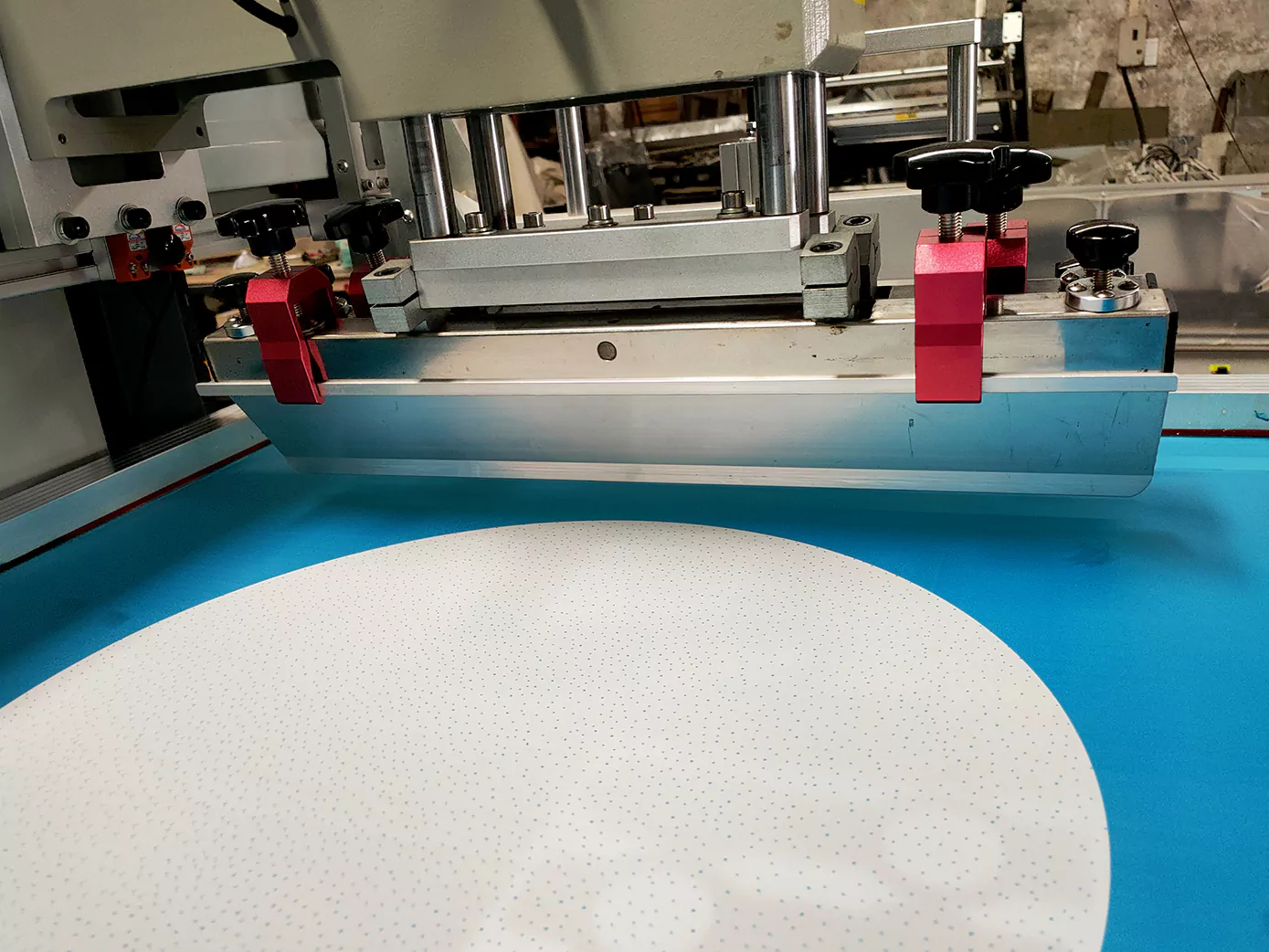

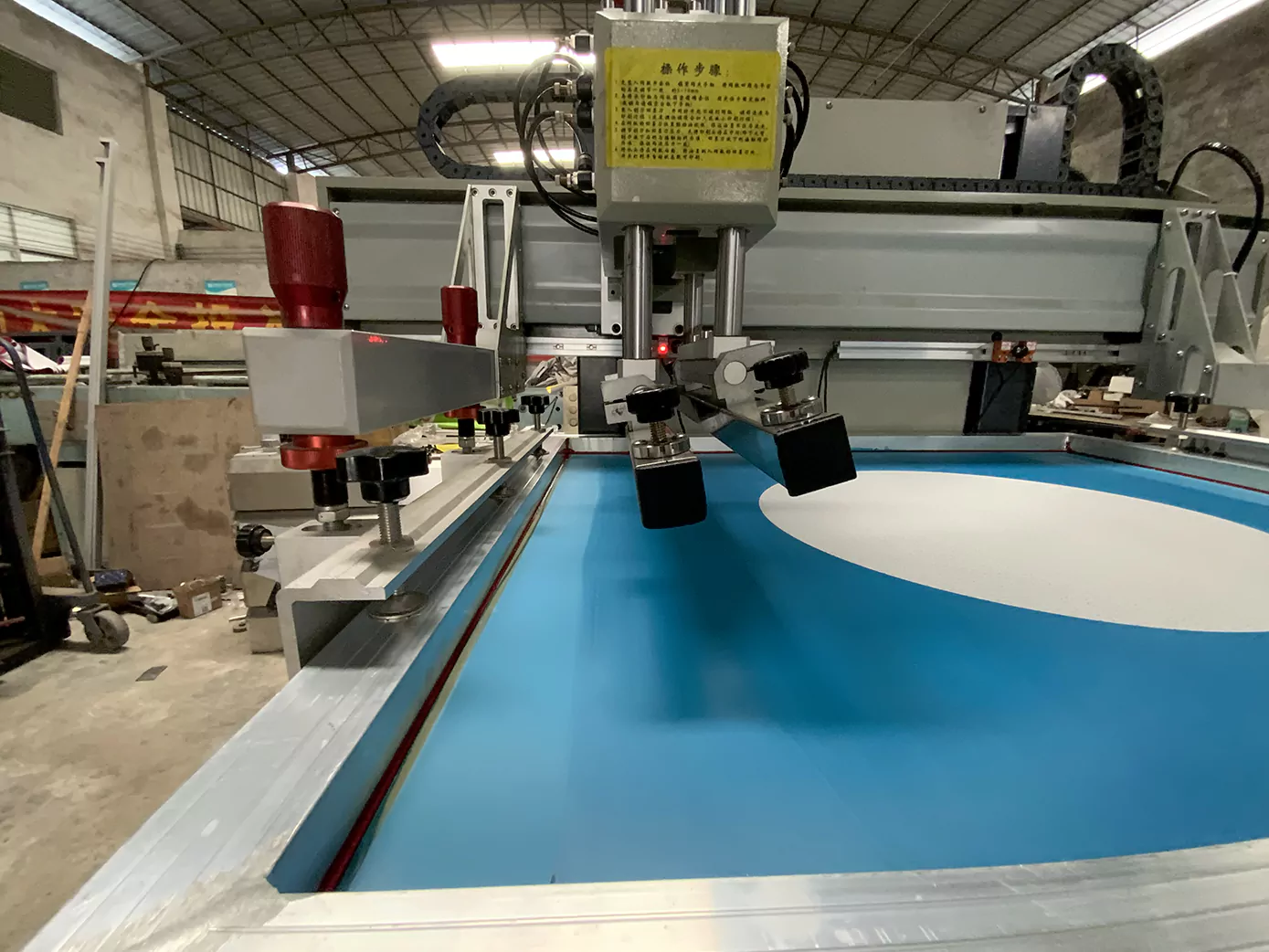

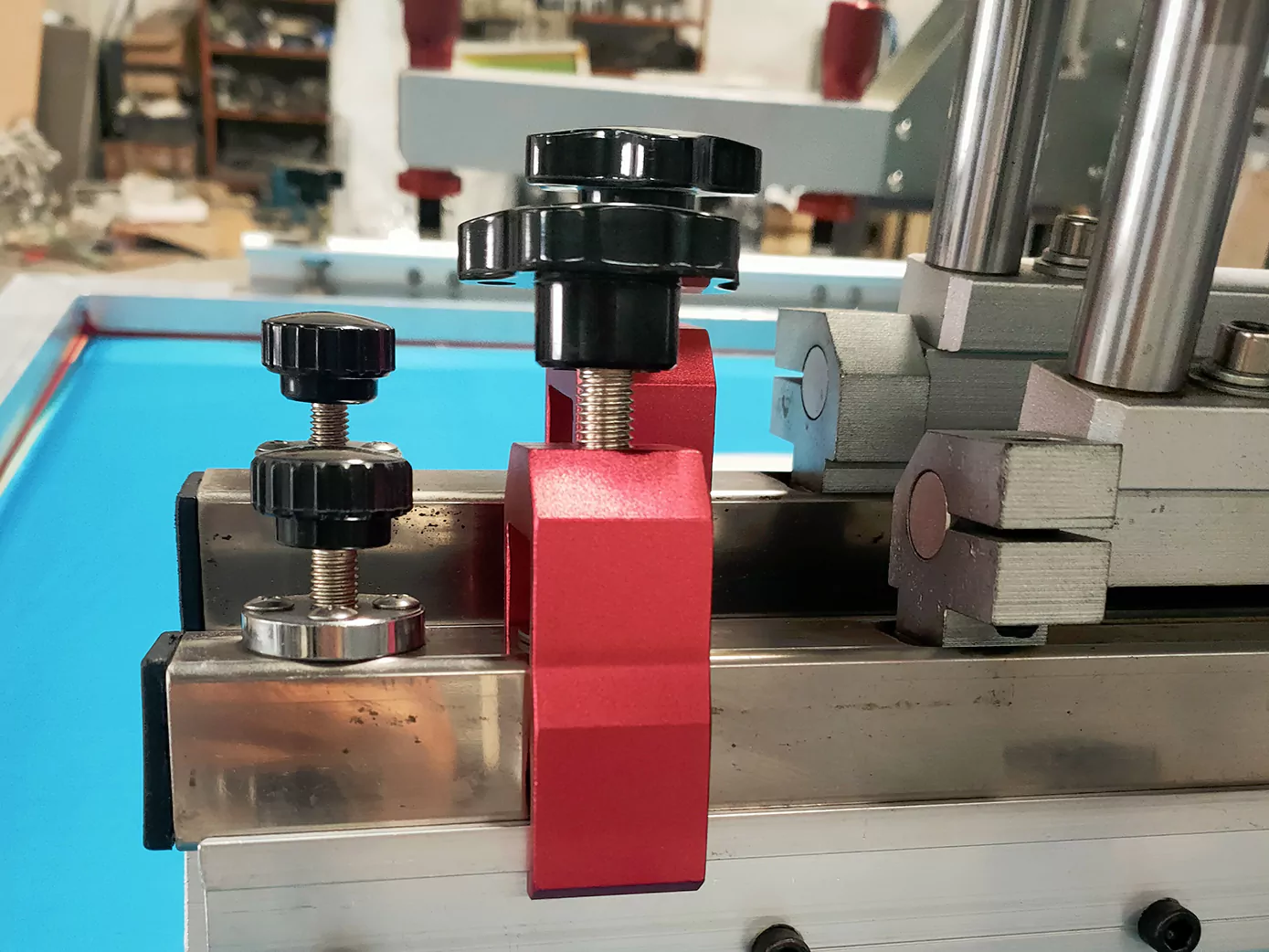

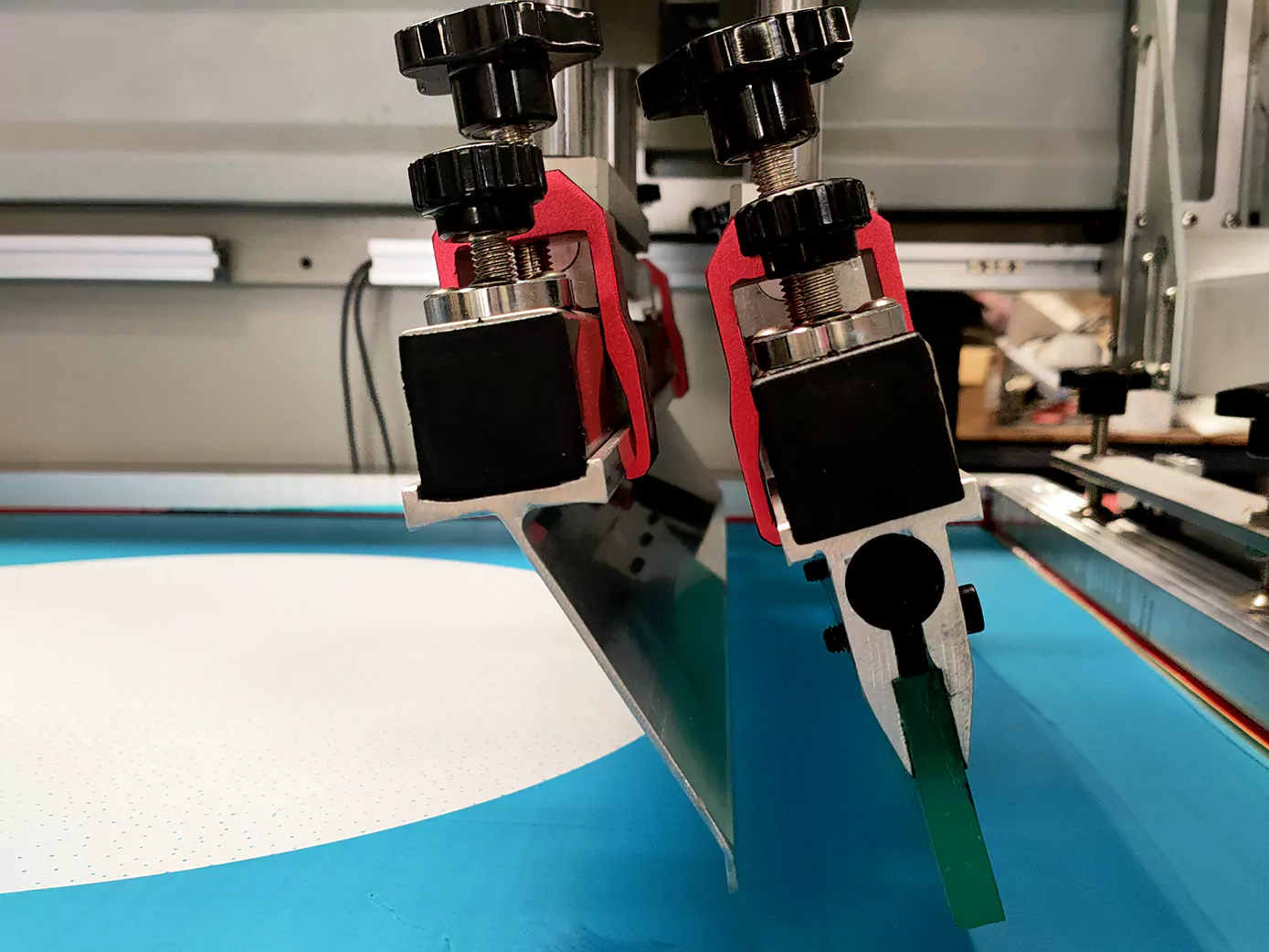

Machine detail show.

Other major components

1.Jacking system:

A device that controls the entire upper and lower parts of the grid.

2.Left and right drive:

A device that controls the left and right movement of the entire print head.

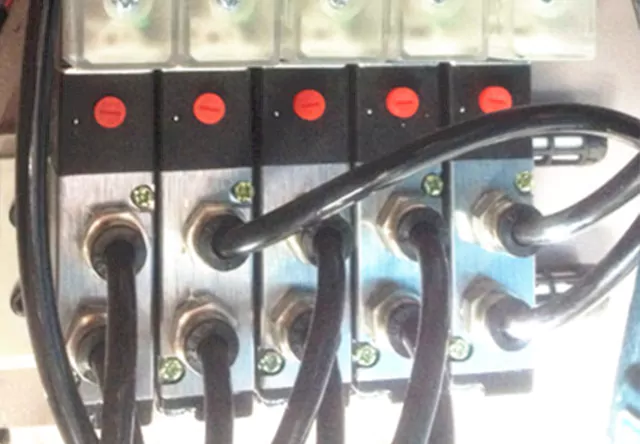

3.Solenoid valve assembly:

A device used to control the movement of all cylinders in a machine.

4.Distribution box:

Used to control the power supply, motor and microcomputer drive function.

Installation and connection of machines:

- Make a corresponding screen according to the pattern size required for printing.

- Make a set of scraper and return knife to match the length of the substrate.

- The scraper and the ink knife are respectively installed in the corresponding position of the machine, and fixed.

- Place the net board on the front and rear net clips, and secure.

- Adjust the net plate parallel to the workbench.

- Please adjust the scraper and ink knife parallel to the screen (based on the screen), and according to the actual needs of the substrate in the range of 65°-85° adjust the scraper tilt.

- Adjust the printing stroke according to the size of the printing pattern (adjust the front and back position of the induction switch).

- According to the thickness of the substrate to adjust the size of the network from the ground to the appropriate.

- Printing speed adjustment: press the speed knob to adjust slowly to reach the appropriate speed when the machine is in air transportation.

- Lock all handles in corresponding positions to ensure accurate nesting.

- Adjust the ink into the screen behind the blank position.。

- According to the substrate thickness, equipped with three corresponding positioner, and paste firmly.

- Equipped with appropriate amount of washing water, such as broken step, so as to clear screen version.

- Good power supply origin, can start production.