Blow molding is a process of forming plastics into various shapes by blowing a mixture of gas and plastic onto a rotating mandrel. The process is similar to injection molding, but instead of using metal to form the part, it uses plastic.

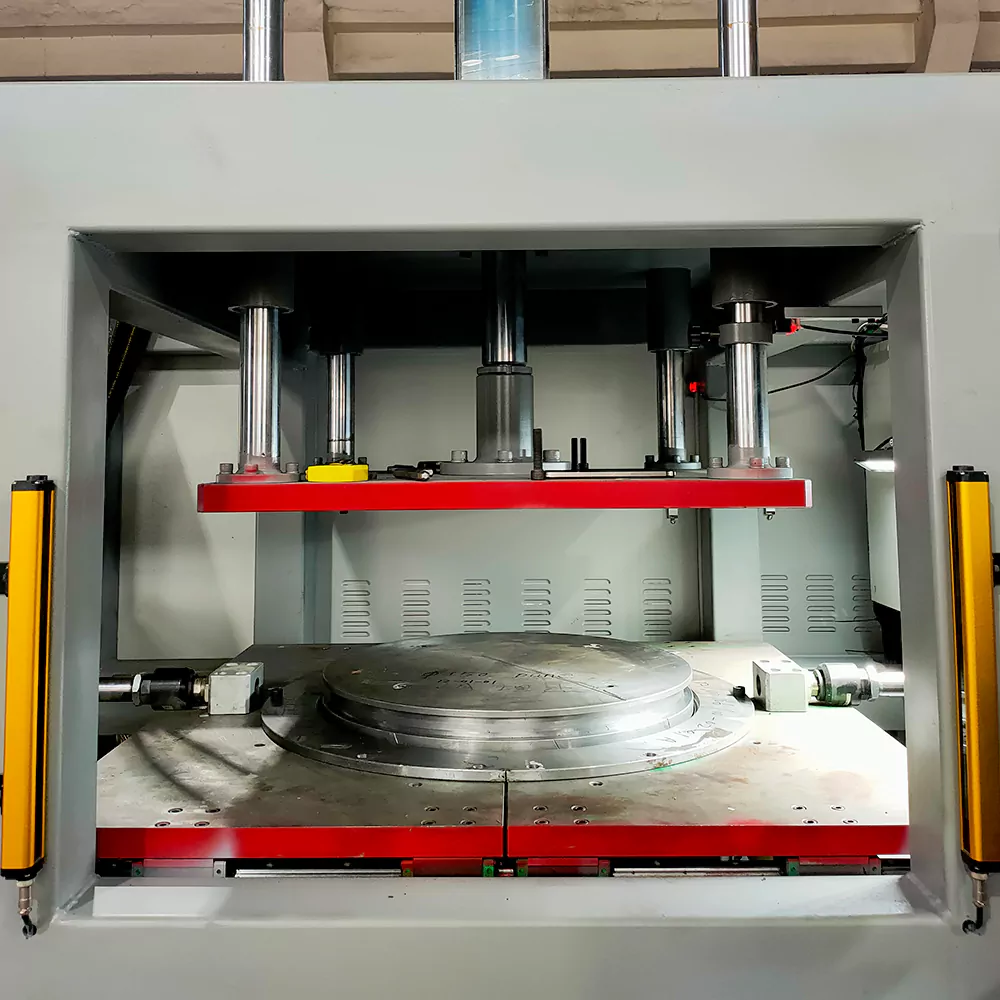

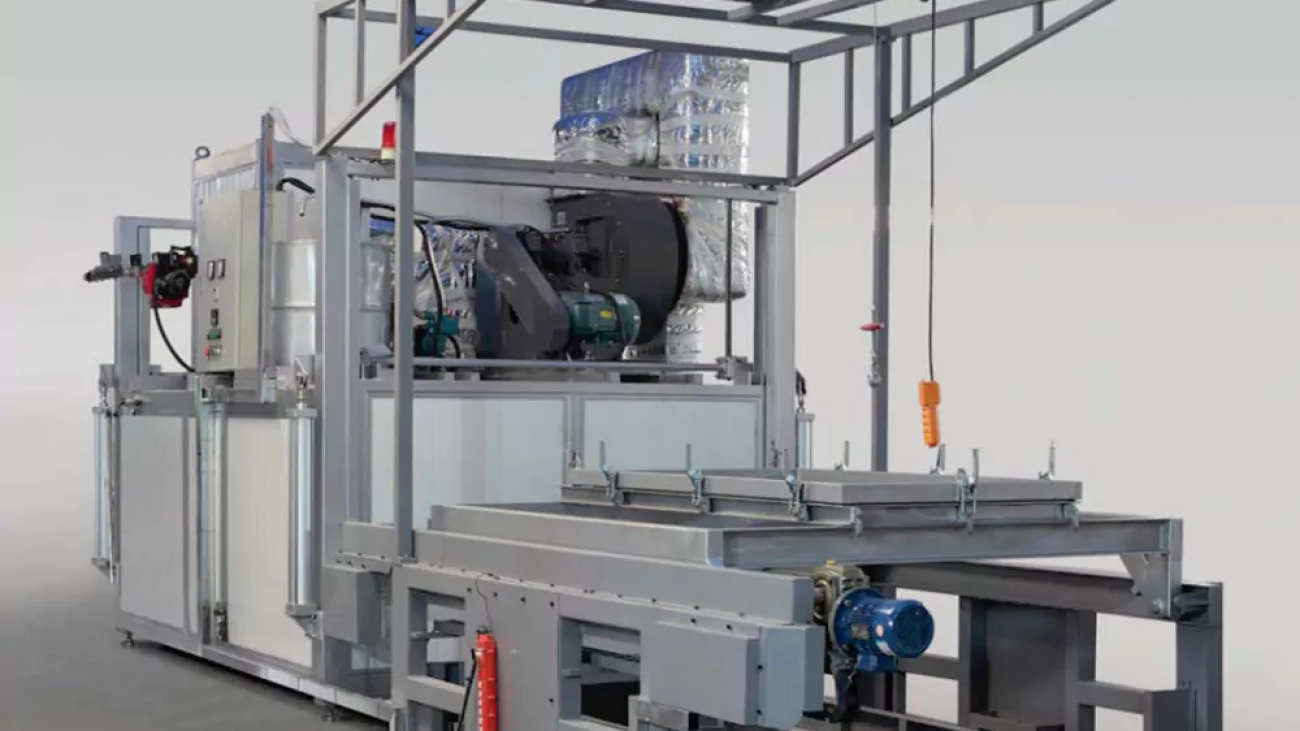

Blow Molding Machine:

The benefits of a blow molding machine include:

Compact size – The small size of the finished product makes it easy for consumers to store and transport

Low cost – The equipment used in blow molding does not require expensive tooling or molds, so it is less expensive than injection molding.

No waste – Because there is no need for complex tooling or molds, there is very little waste from the process. This can be especially beneficial when dealing with high-value products such as medical devices, electronics, and toys.

Predictable quality – Because there are no moving parts in blow molding machines, they are much easier to maintain than injection molders. This means that you can run them more frequently and still maintain the same level of quality as before.

Wide application – It has good heat conductivity, excellent resistance to heat corrosion, and long service life; it doesn’t affect the human body when working; it can be widely applied in other fields such as medicine packaging film extrusion film processing, etc.; it can also be used for making a variety of plastic products including toys packaging cups, etc.

More convenience for users – Blow Molding Machine is easy to use and convenient to operate; it can be widely used in different industries such as plastic bags, cups, bottles, etc.; it is suitable for producing various products according to customers’ requirements

If you want to buy Blow Molding Machine online, then without any doubt, the platform of Romas Machinery is best for you.

Romas Machinery:

Our company focuses on the research and development of ceiling lamps, devoting great attention to technological research and development, technological innovation, and advanced design software.

Conclusion:

Blow molding machines will work wonders for your business. Just do contact us and we will deliver the best product to you.