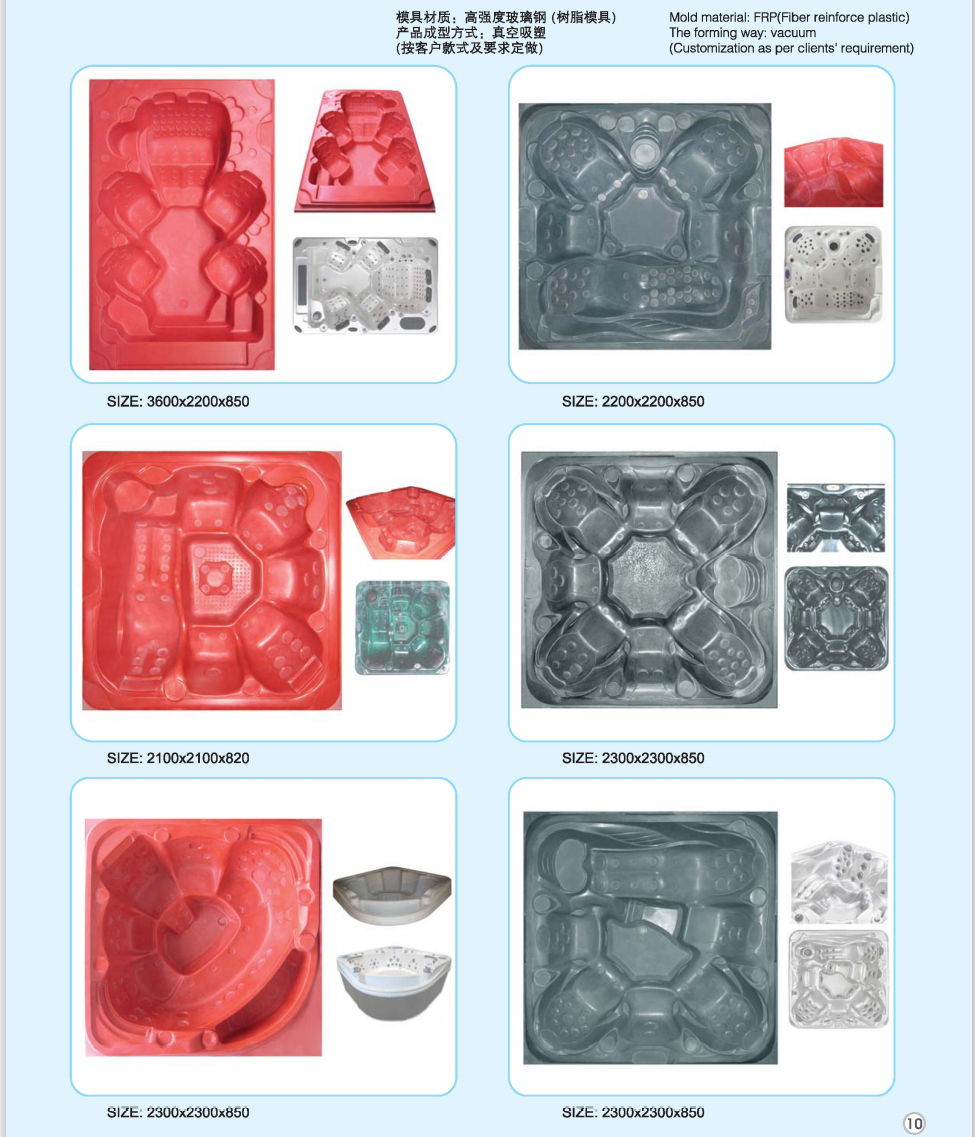

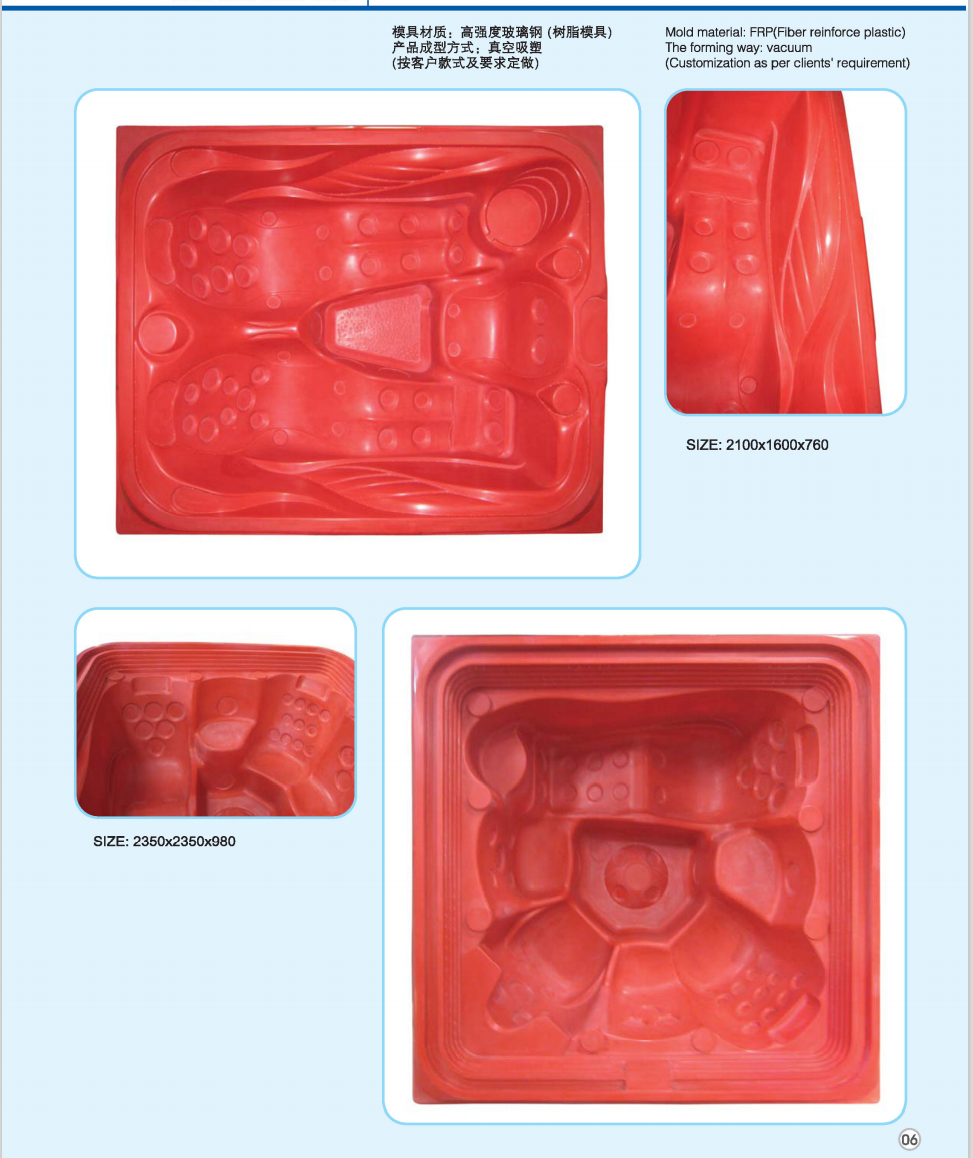

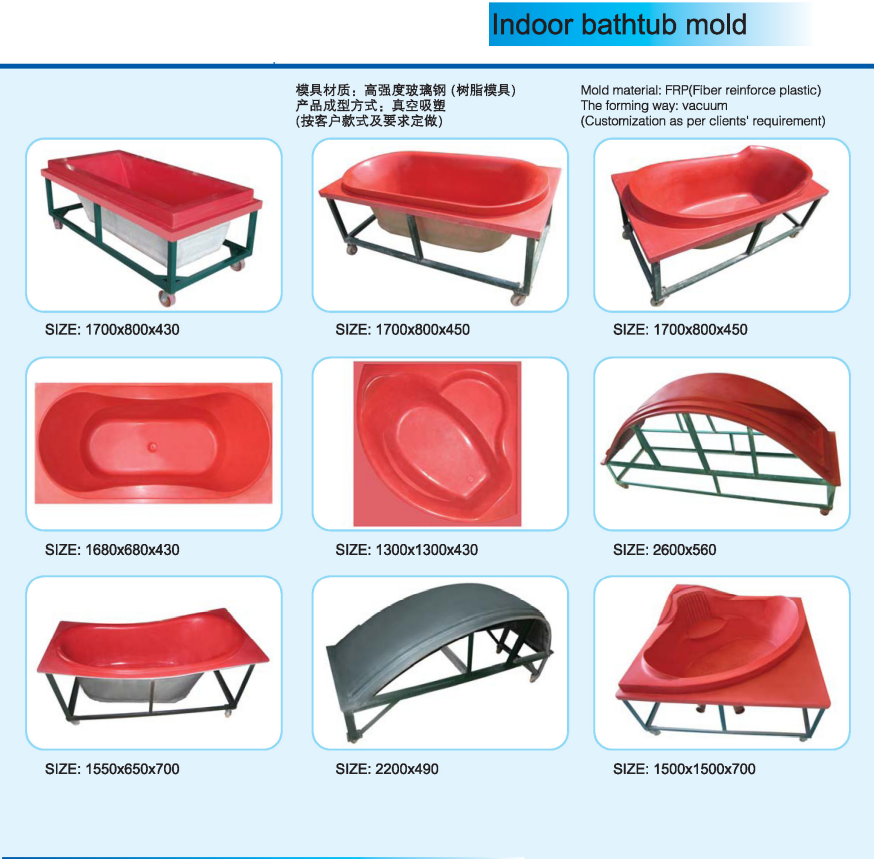

Description

How to make the mold process?

1. make the drawing as per the requirement of customers or the drawings or pictures from them.

- send the drawings to the customer by email and as them to confirm the position of air valve, water valve and skimmer etc. as well as the layout of the jets. If there is any modification, the amended drawing will be resent until final confirmation

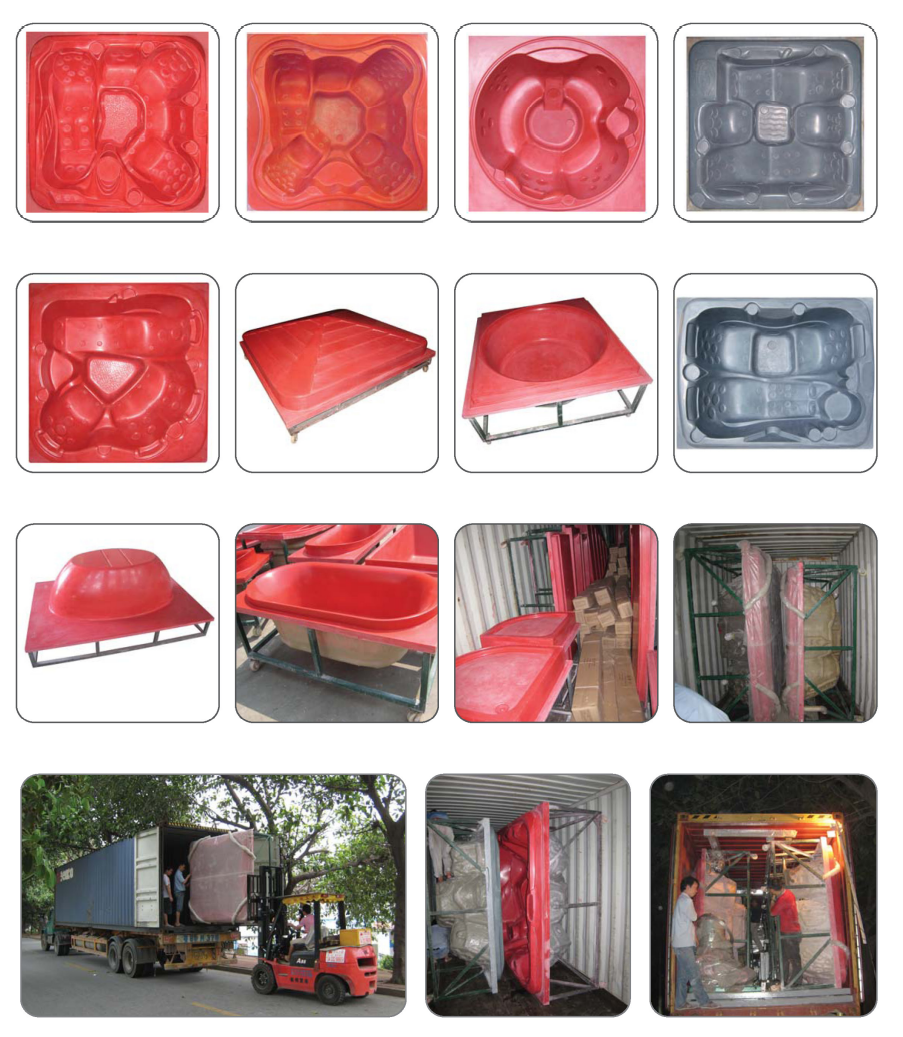

- make the plaster mold as per the final drawing an then send the pictures to customers for confirmation by email. Any modification, the plaster mold will be change until final confirmation

- After finish the plaster mold, the next is to make stage mold. The surface of the stage mold will be timed and polist to get a perfect surface

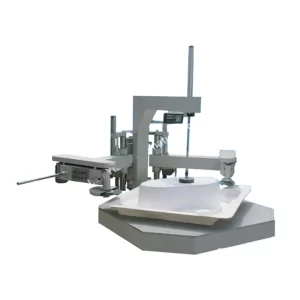

- Make the production mold: repolish and retrimed carefull until it meets the highest requirement of suction mold.

Our advantage

Comprehensive design level: 21-years experience in mold and products manufacturing make product design more reasonable, more beautiful, more comfortable.

High efficient: professional manufacture, team spirit, high efficient let you capture market more guarantee; the shortest delivery time for spa mold is 30days.

Exquisite in workmanship: professional technology, strict quality control, stop mold appear defect like rough, bubble, deformation, flaw completely.

Concise program: to lower technician press mostly, all the design we try our best to do it for you.

Guarantee maintain: 2 years free maintain for local area client, maintain technology can be offer free toother area.