Description

Main performance:

RW series automatic roller screen printing machine is a high-speed, high-precision automatic sheet fed screen printing machine successfully developed by our company. It has a wide range of printing and is suitable for monochrome printing and multi-color overprint of sheet materials such as gold and silver cardboard, transfer paper and whiteboard, plastic film (polyethylene, polyester and polypropylene), self-adhesive and so on. At the same time, local UV glazing can also be carried out on printed matter.

The machine can satisfactorily carry out a variety of printing, especially for the overprint of gold and silver in UV imitation metal ink. It is mainly used not only for the decal printing of trademarks such as ceramics, glass, enamel, bicycles, sewing machines, furniture and lacquerware, but also for the printing of packaging and decoration of soft paper boxes, cartons and posters. The machine adopts centralized control, simple operation and high sensitivity, so it is widely valued and welcomed by the printing industry.

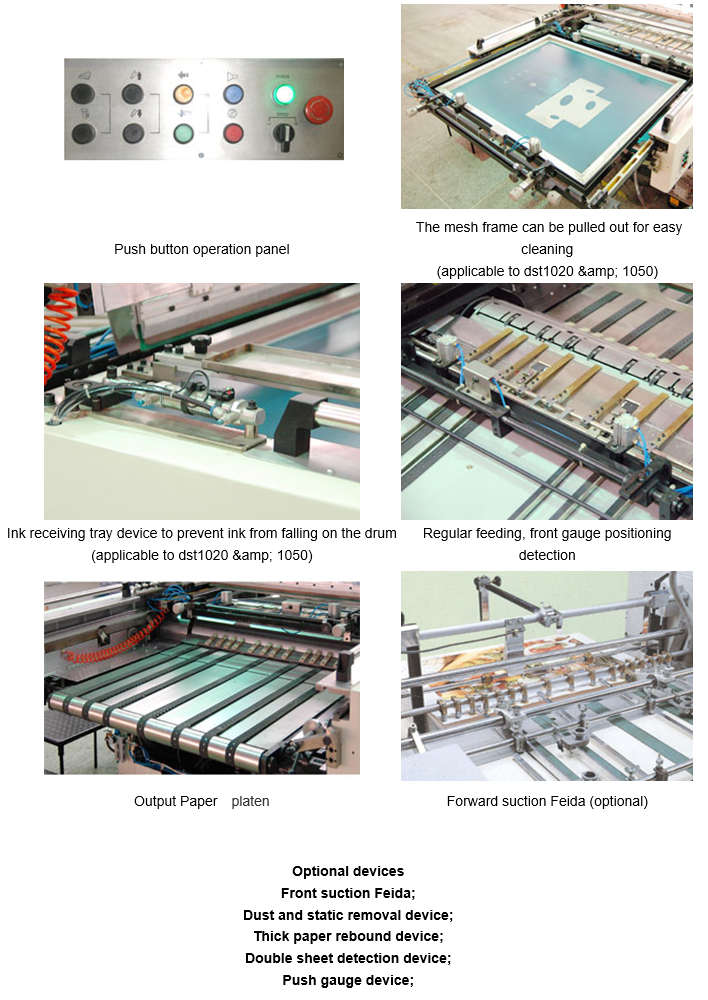

Main features:

- Japanese Mitsubishi frequency converter and PLC programmable controller are used to control the operation of the whole machine. More than 90% of imported components such as Fuji and OMRON make the machine integrate electromechanical integration technology, with many advantages such as high energy level and high stability.

- The whole process is automatically monitored and detected, and the printing registration accuracy is 0.1mm.

- The printing ink is plump, bright in color, strong three-dimensional sense, large covering power, and the ink layer thickness is 30-40 microns, which is superior to other forms of printing machines.

- Automatic continuous paper feeding; The paper feeding mode is divided into general (GAP) type and flow (stack) type, which can be switched freely according to the material thickness of different prints;

- The paper outlet table can be turned 90 degrees to facilitate screen cleaning;

- The screen is easy to load and unload, and the screen position can be adjusted freely;

- This series can be connected with the rear dryer to form an automatic printing production line.

Technical parameters:

| Model | RW-720 | RW-780 | RW-1020 |

| Maximum paper size (mm) | 720×520 | 780×540 | 1020×740 |

| Minimum paper size (mm) | 350×270 | 350×270 | 560×350 |

| Maximum printing area (mm) | 720×500 | 780×520 | 1020×720 |

| *Paper thickness (G / m2) | 90-350 | 90-350 | 120-350 |

| Mesh frame size (mm) | 880×880 | 940×940 | 1280×1140 |

| *Printing speed (PCS /H) | 1000–3600 | 1000—3300 | 1000—3000 |

| Total power (KW) | 7.58 | 7.78 | 10.39 |

| Total weight (KG) | 3500 | 3800 | 5500 |

| Overall dimension (mm) | 4350×1960×1270 | 4350×2020×1270 | 4500×2450×1320 |

Main characteristics