Description

1.We have experienced design group can make design according to customers requirements. OEM is availabel.

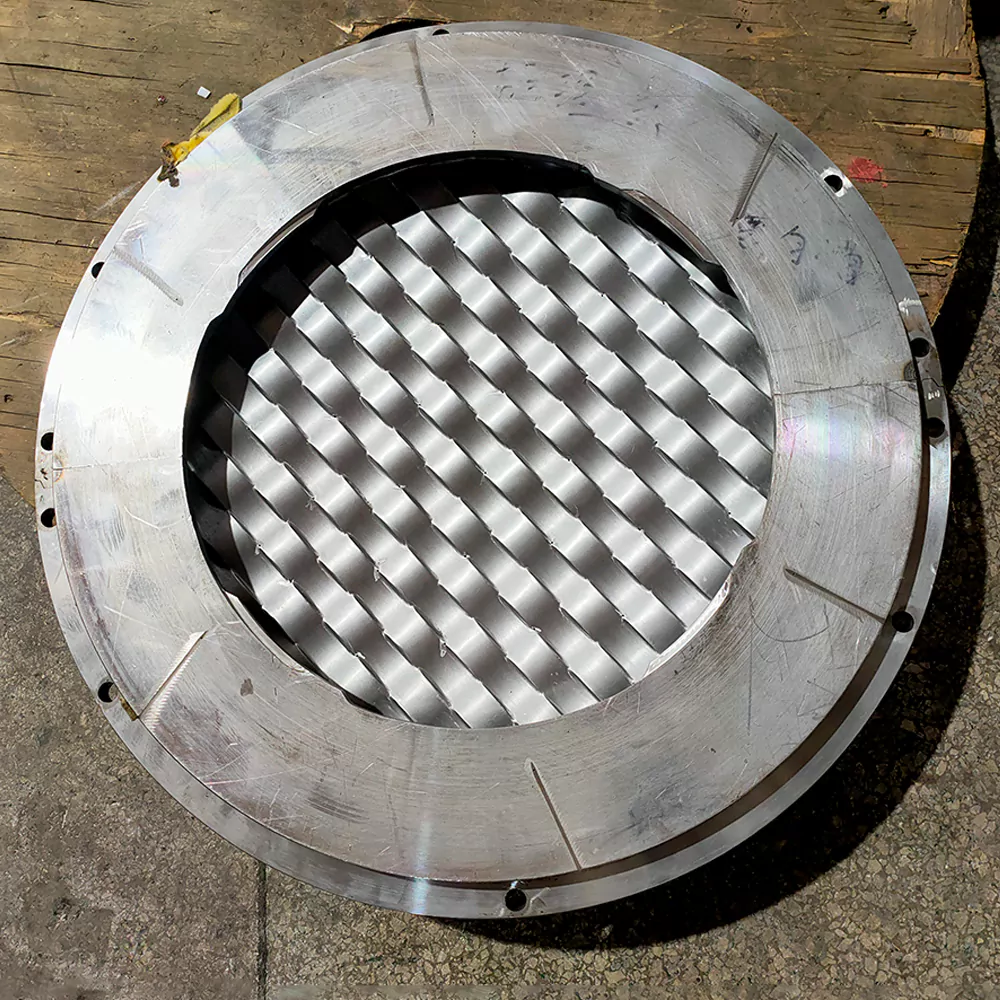

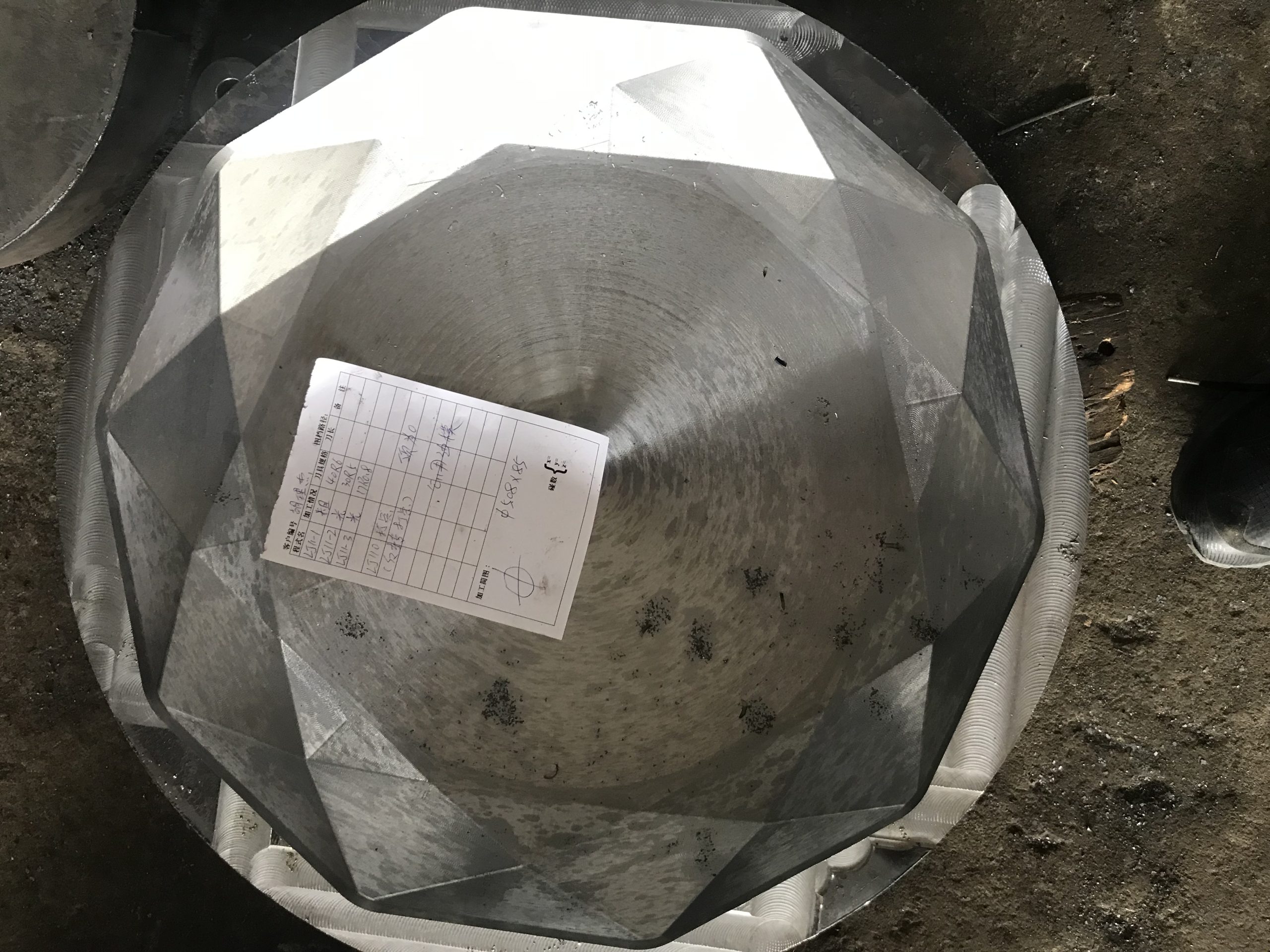

2.Our factory has modern equipment, such as low-speed wire cutting machines, CNCs, EDM machine tools, and plain grinding tools.

3.Also, we are strict in quality control; we lay stress on supporting services…We expect rapid and steady development, moreover we expect to share the pleasure of win-win success with our cooperators.

4.The factory has accumulated years of professional experience in plastic, with a number of imported high-speed automated production lines and strong technical force.

5.Our company won a high reputation for our fast delivery time, great quality and favorable price. We are confident that we have the capability to meet your requirements.

Mold Process

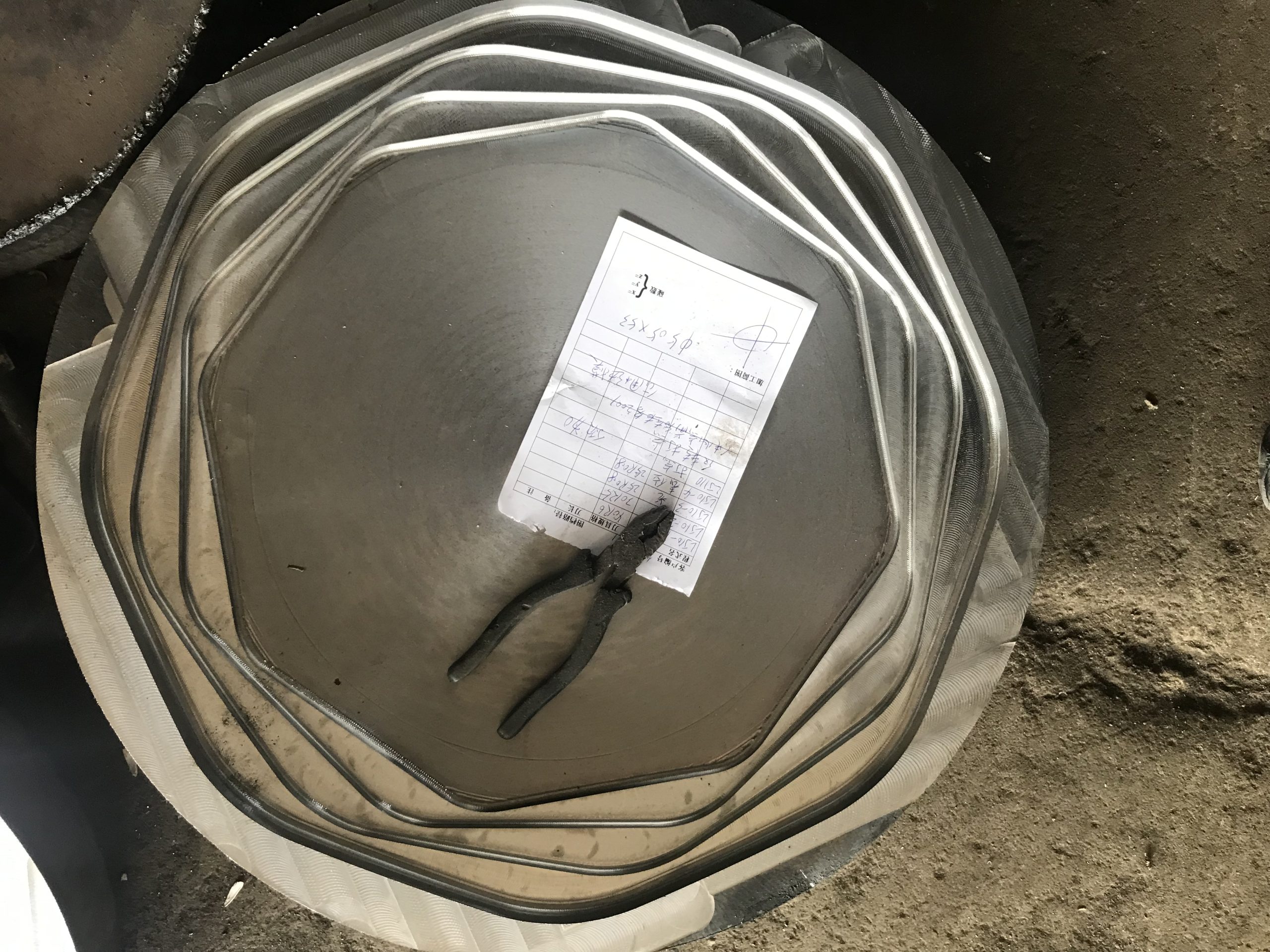

1st. step

Receive the sample or drawing from client, or the client give us the requirement.

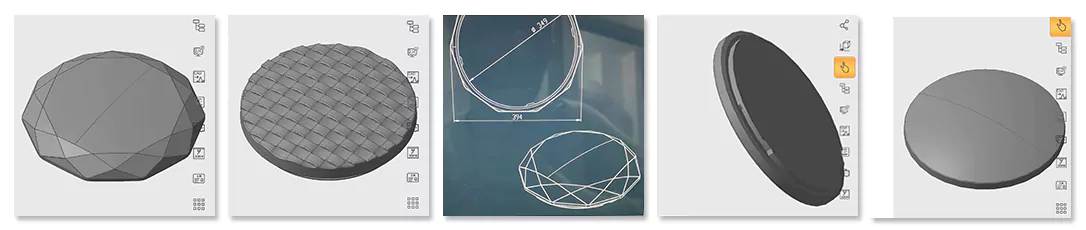

2nd. step

Our engineer dept. to draw the 3D or 2D drawing, we can offer UG,Pro/E,solidworks, CAD and CAX…etc. drawing for client to check.

3rd. step

After the client checks the drawing, we start to process the molds.

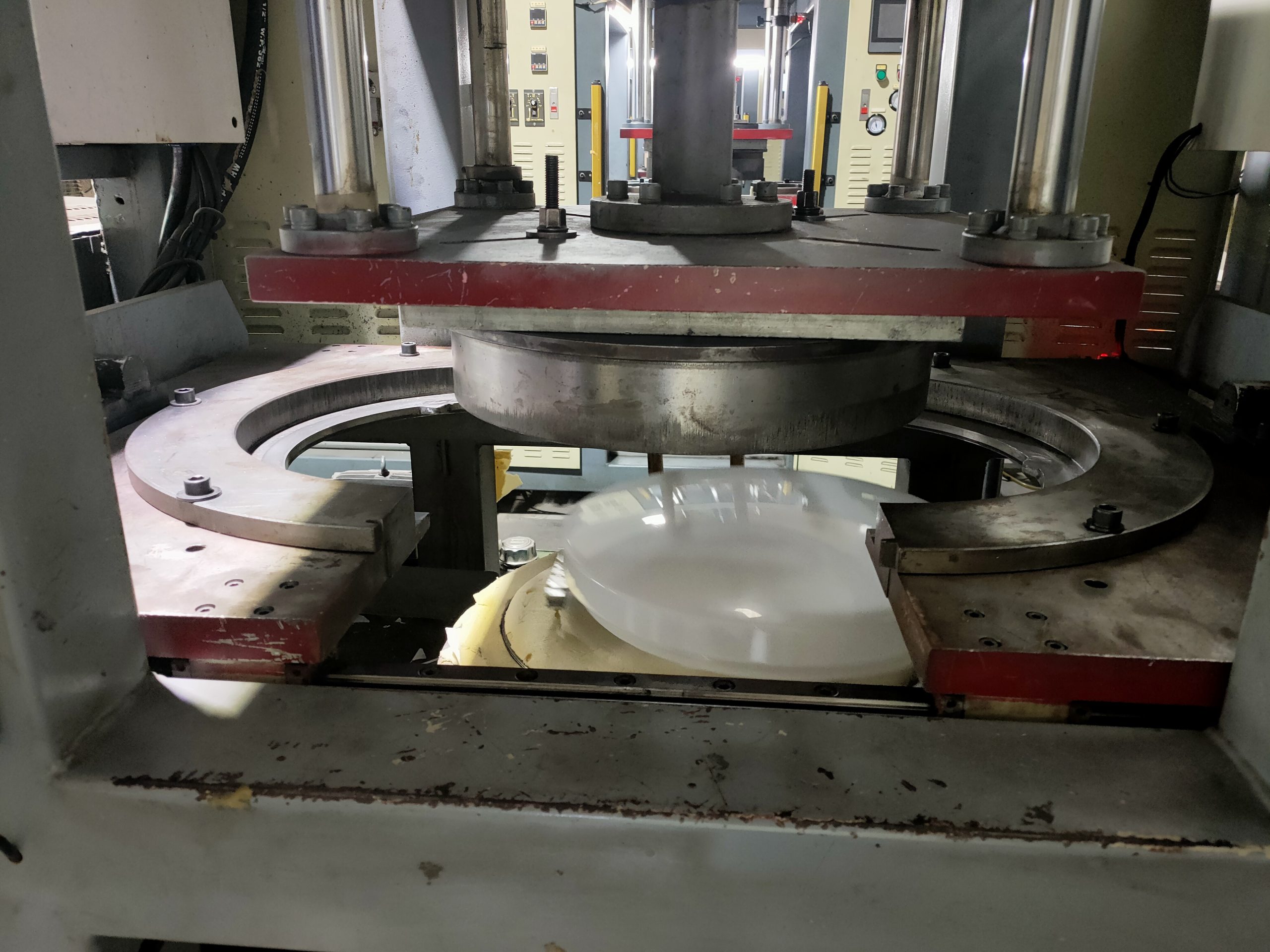

4th. step

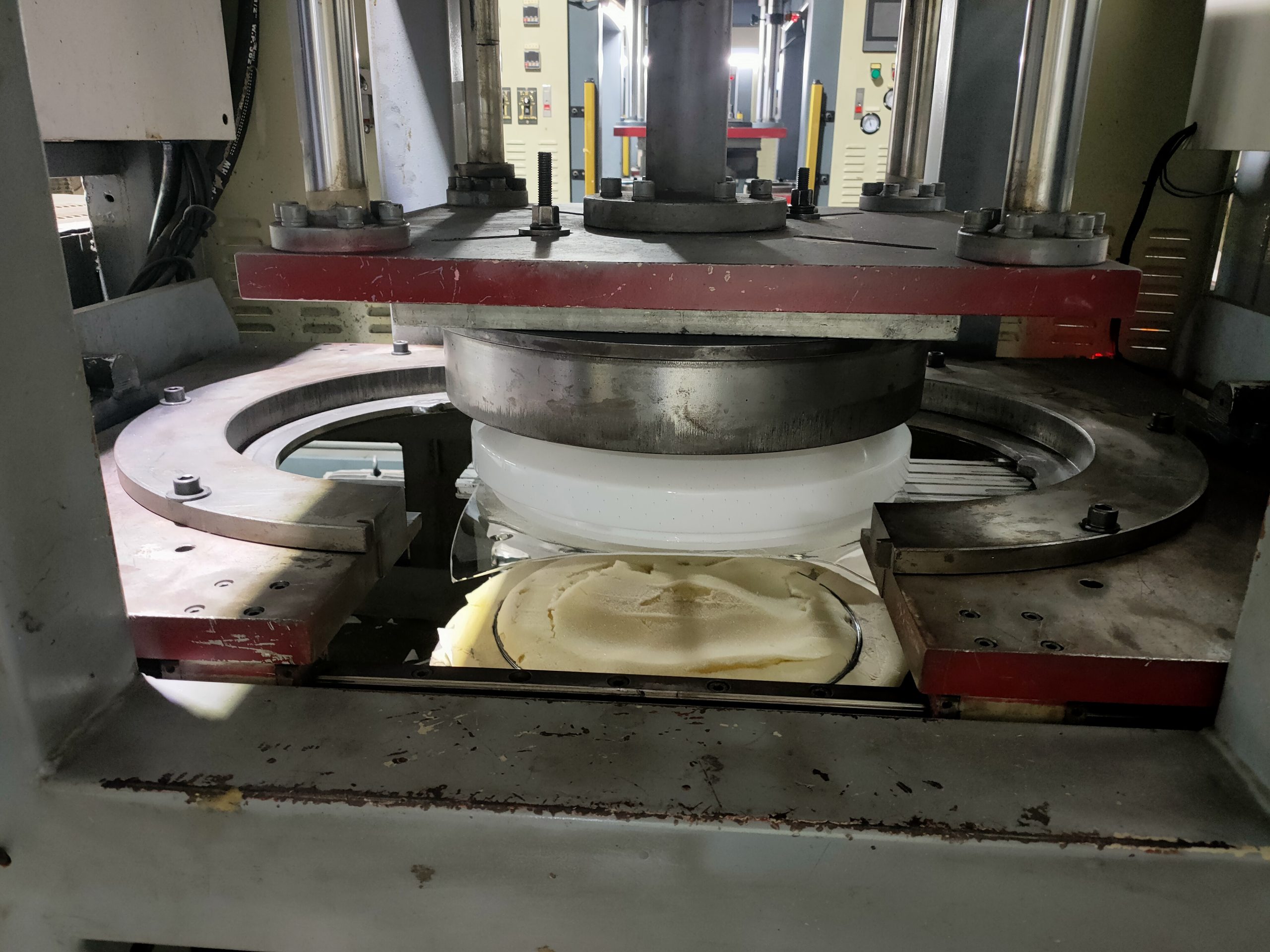

Test the molds, and send the sample to our client to check it. Or invite the client to our factory to check. Because we the machine manufactory, we have the thermoforming machine to test the molds anytime.

5th. step

If the client thinks the mold is OK, we send the mold to them. If not, we modify the mold to meet the client’s requirements.