A vacuum forming machine is an advanced machine that is specially designed to carry out the vacuum forming process. In order to introduce a vacuum forming machine, it is necessary for you to understand what the vacuum forming process is. Interested? Continue reading…

Vacuum forming process:

Vacuum forming is a type of thermoforming process that is helpful in the moulding of plastic in a specific shape. In this process, the sheet of plastic is heated to a specific temperature and then moulded to a three-dimensional shape using compressed air as well as a vacuum forming machine.

Working mode of the machine:

Vacuum forming is utilized in a variety of production processes, from small bespoke pieces made on desktop devices to massive parts made on automated industrial equipment. Furthermore, the most basic method of plastic thermoforming is vacuum forming. It employs a single mold and vacuum pressure to achieve the required component shape. It’s perfect for pieces that just need to be perfectly shaped on one side, like food packaging or electronics.

- A sheet of plastic is clamped into place in an open frame.

- The plastic sheet is usually softened using a heat source until it reaches the correct forming temperature and becomes flexible.

- The framework containing the heated, flexible plastic sheet is lowered over a mold and suctioned into place on the other side.

- Once the plastic has been formed around the mold, it must cool. For larger components, fans or mist are sometimes used to speed up this portion of the manufacturing process.

- Once the temperature of the plastic lowers (cooled down), it may be removed from the mold and also from the framework.

- The extra material will need to be taken away from the finished portion, and the edges may need to be polished or trimmed (depending upon the situation).

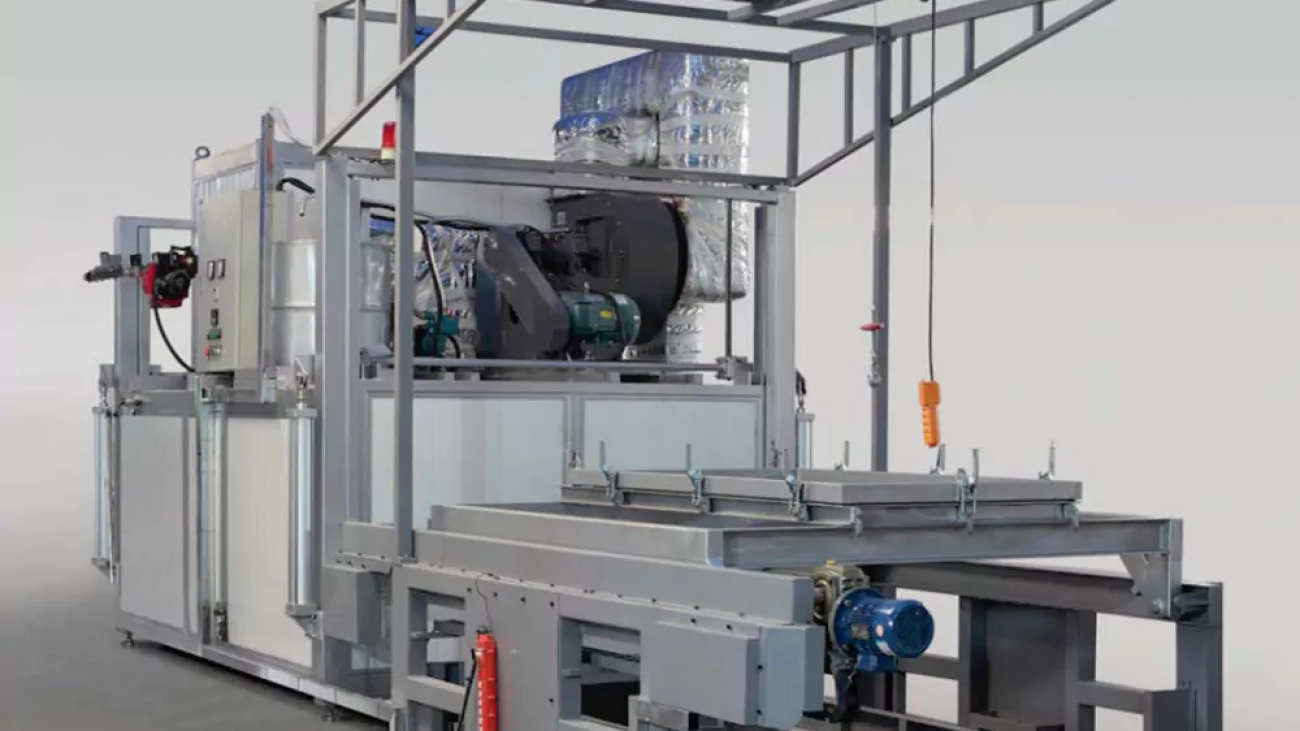

Best supplier of automated machinery:

Romas Machinery technology co, Ltd is the world’s best vacuum forming machine supplier. It is a professional company that deals with a wide range of automated machinery, and the best part is it sells all the equipment at reasonable prices. Now you can buy vacuum forming and other related machinery online via Romas Machinery.